THE COMPETITIVE ADVANTAGES OF SPECIAL COLD-DRAWN PROFILES BASED ON CUSTOMER’S DRAWING

COST-EFFICIENT SOLUTIONS

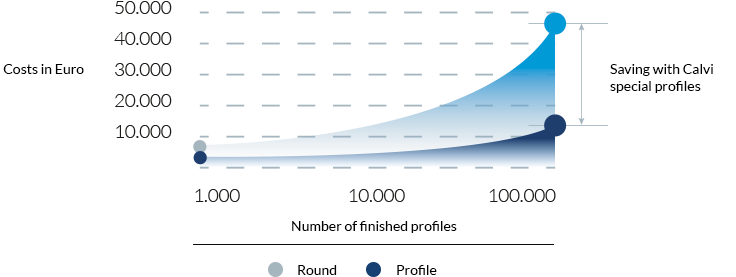

Comparison of total production costs:

profile machined from a round profile vs. Calvi cold drawn profiles.

FROM A ROUND

FINISHED MACHINED PROFILE

FROM A ROUND

Round bar weight 19,9 kg/m

FROM A PROFILE:

CALVI FINISHED COLD DRAWN

CALVI FINISHED COLD DRAWN

PROFILE BASED ON CUSTOMER’S DRAWING

Weight of shaped bar Calvi 2.9 kg/m

0

less scrap than

round/export

processing.

Indicative data and information only, used as an example.

THE ADVANTAGES OF USING SPECIAL COLD-DRAWN PROFILES

The following example shows the necessary machining operations starting from a round bar compared to a Calvi SpA shaped bar.

540 gr

Weight

0' 20''

Processing

28 gr

Waste

281 gr

Weight

0' 20''

Processing

18 gr

Waste

540 gr

Weight

0' 20''

Processing

28 gr

Waste

540 gr

Weight

0' 20''

Processing

28 gr

Waste

540 gr

Weight

0' 20''

Processing

28 gr

Waste

540 gr

Weight

0' 20''

Processing

28 gr

Waste

540 gr

Weight

0' 20''

Processing

28 gr

Waste

281 gr

Weight

0' 20''

Processing

18 gr

Waste

Data and information purely indicative, used as an example